Various cross-sectional shapes

We can produce tapered shapes, composite structures (core-sheath, side-by-side, sandwich), hollow yarns, and irregularly shaped monofilaments.

-

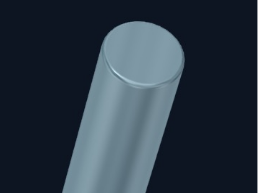

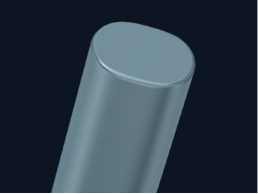

Circular

-

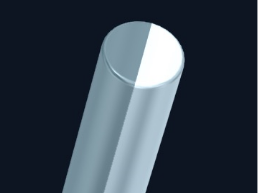

Side-by-side

-

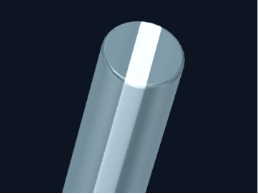

Sandwich

-

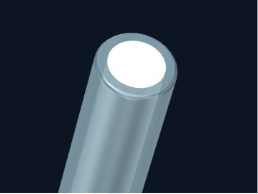

Core-sheath

-

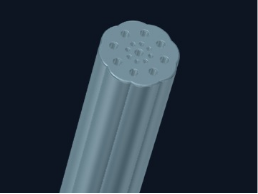

Hollow(Porous holes)

-

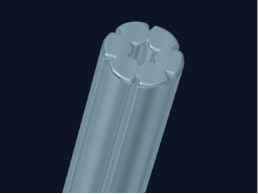

Hollow(Petal shape)

-

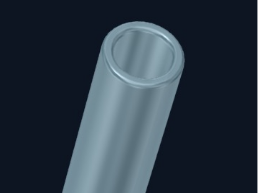

Hollow (Tube)

-

Pentagonal

-

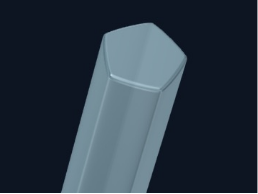

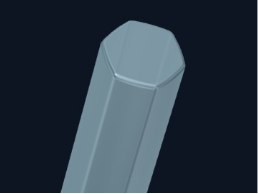

Hexagonal

-

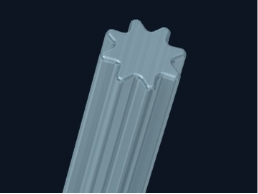

Star

-

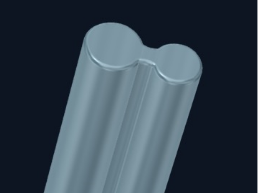

Figure “8”

-

Ellipse

| shapes | Description |

|---|---|

| Circular | Most basic shape. Easy to handle due to its superior strength, abrasion resistance, and straightness. |

| Side-by-side | Two different components or different colors are arranged in parallel. If materials with different shrinkage rates are laminated together, they become a stretchy yarn that crimps on its own. |

| Sandwich | The core resin is sandwiched between the two side resins. Unlike the core-sheath structure, the surface of the sandwiched component is also exposed. Combination of different components is possible. Also, a combination of two different colors can be used to express the exterior tint. |

| Core-sheath | The core component is covered by the sheath component. The ratio can be 1:9, 2:8, 5:5, etc. The use of a high physical property’s polymer in the core and a low melting point polymer in the sheath can provide functionality that is not possible with a single-layer structure, such as thermo-bonding properties. |

| Hollow (Porous holes) | Even the 20% hollow ratio can maintain the strength similar to that of a circular cross section. It can provide light weight, heat retention, bulkiness, and a unique luster due to the refraction and scattering of light. |

| Hollow (Petal shape) | Like a flower petal. It has an incised portion, which reduces the coefficient of contact friction. This structure is best suited for safety applications where strength against friction is required, but the material should break when a certain amount of force is applied. |

| Hollow (Tube) | The fiber has large cavities inside and has a very low specific gravity. The hollow can contain air, making it extremely heat-retentive. It can also be used as a covering material by passing threads inside the hollow. The hollow size is adjustable. |

| Pentagonal, Hexagonal, Star-shaped | Anchoring and cutting effects are also given by the corners, which make it easier for materials to hook together. In tennis racket strings, some different cross sections are used to give spin performance. |

| Figure “8” | Used for eyeglass frames. The shape of the side that is threaded through the frame and the side that fits the lens groove are different, requiring delicate shape control to securely fit the lens on flame. |

| Ellipse | They are easily overlap each other without any gaps between them. Long and short diameters can be controlled according to your requirements. |