Transformation

of materials

Sunline creates new values for monofilament fibers by offering highly

advanced Japanese technology to the world.

As Japan's leading fishing line manufacturer,

Sunline has very specialized spinning and secondary processing technologies

that we have developed and refined for over 45 years.

Sunline receives numerous of requests annually for manufacturing of

prototypes and joint developments in a wide array of industries.

The transformation of material

as you wish

The transformation of materials as you wish

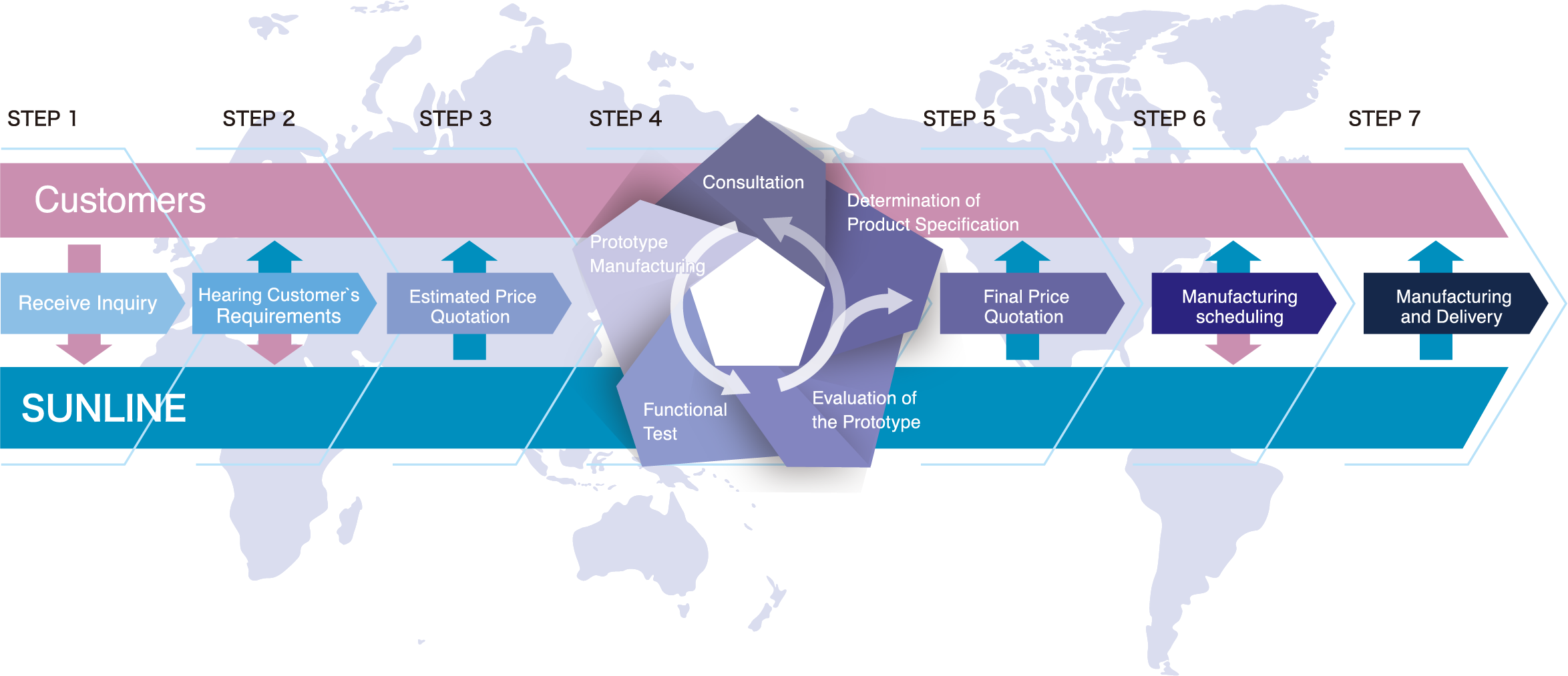

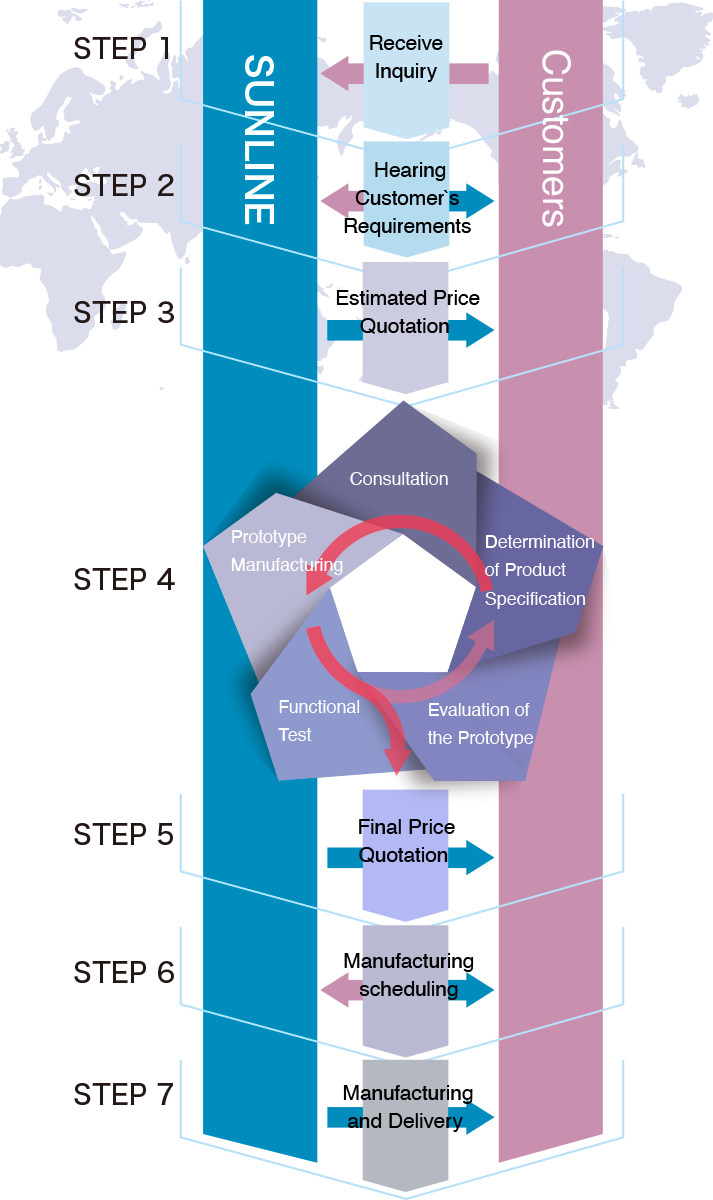

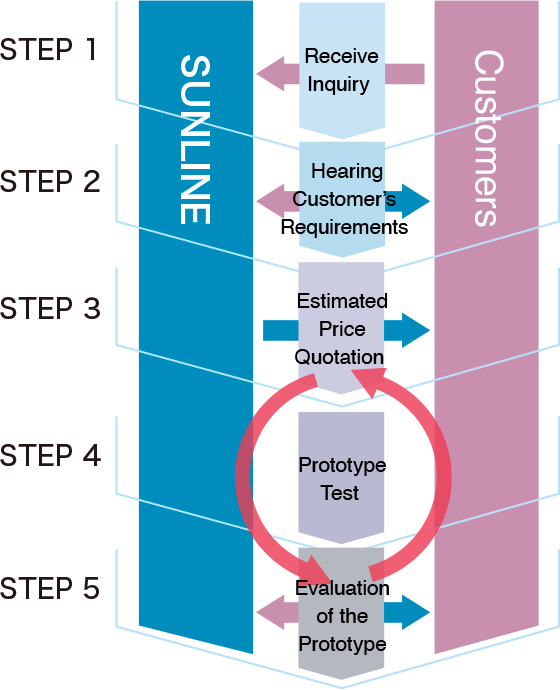

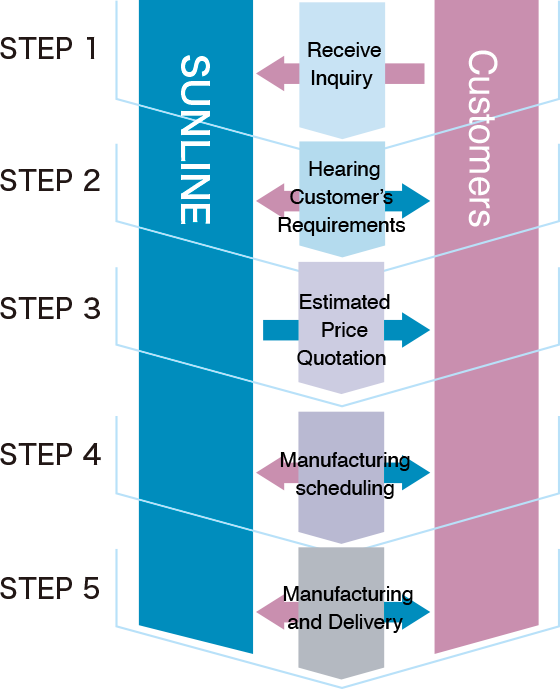

Workflow until Order

Regardless of the scale of the project, we will work with you

to meet your challenges and work together to achieve your goals.

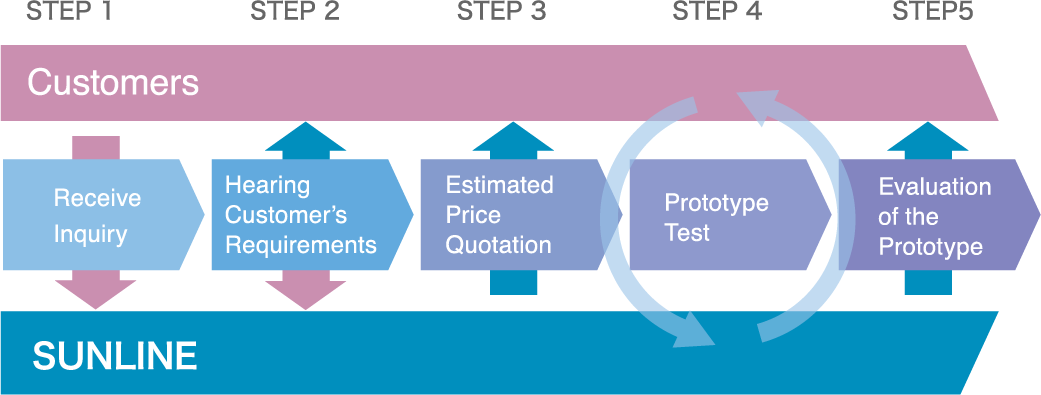

Case 2, Only Test by Prototype

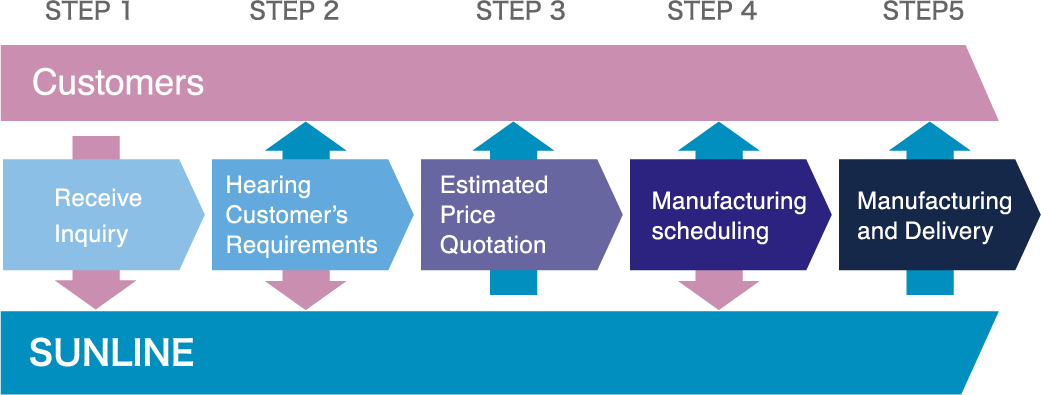

Case 3, Only Order

Learn about SUNLINE

-

comming soon

-

comming soon

-

comming soon

SUNLINE’s monofilament

and multifilament fibers

are

used in a wide array of industries.

-

Commercial Fishing Industries

The line used in fishing traps is a lifeline for fisheries. Depending on the target fish and fishing method, the characteristics required of the line are quite different. We listen carefully to what fishermen need and suggest the best line, developed from the raw material and coating agent stages.

-

Medical Industries

While monofilaments for sutures have the advantages of good tissue permeability and resistance to infection due to the absence of bacteria, they have the disadvantage of being taut and easily unknotted. We have the technology to optimize the quality of sutures to make them easier for doctors to handle.

-

Musical Instrument Industries

Stringed instruments play different sounds depending on very delicate differences in the quality of it’s strings. Our spinning technology expands the possibilities of the sounds you want to produce.

-

Sporting Goods Industries

Technology in sports is evolving daily. To support the performance of outstanding world-class athletes, it is necessary to combine characteristics in terms of strength, spin performance, resilience, shock absorption, durability, and hitting sound. We not only develop nylon and polyester strings, but also strings manufactured of unparalleled materials.

-

Agriculture and Construction industries

Monofilaments are used for various components in agriculture and construction sites. Polyester fibers with excellent weather resistance are used as covering materials. Nylon fibers and UHMWPE are also used for suspension, fall prevention, and bird repellent lines using light specific gravity and high strength. It is being considered as an alternative material for metal wires.

-

Extrusion Materials for FDM-based 3D Printing

Extruded materials for stable stacking require linear stability, moderate hardness, and a suitable coefficient of friction. We can develop monofilaments for Fused Deposition Modeling Machines that match the moldings you require.

-

Apparel Industries

In addition to nylon and polyester, we can also spin thermoplastic resins. Silicone and surfactant oils are also available. We can also provide expert consultation on weaving methods.

-

Apparel Industries

We offer fibers that are fluff resistant, smooth and comfortable to wear, easy to tie, stretchable, and available in a wide variety of colors. Furthermore, our patented technology can give the fiber semi-permanent antibacterial and water-repellent functions.

-

Household Goods Industries

The fiber quality and diameter of toothbrush bristles affects its brushing comfort. Brushes that used to be made of animal hair are being switched to synthetic fibers from the viewpoint of animal protection. We can also reproduce the texture of animal like hair fibers through special processing methods.

-

Artificial Hair

We produce artificial hair using a special processing technology. Our artificial hair has a texture similar to that of human hair, with moderate curl while suppressing the luster characteristics of synthetic fibers. We also offer a wide range of thickness and color variations.

-

Plastic Models & Toys

We offer ultrafine single metal wire for tension wire of ship and airplane models, twisted stainless steel wire for towing tank models, and threads made of elastomeric material with excellent elasticity. Elastomer materials are available in a wide range of colors.

-

Electric Wire Materials

Polyethylene materials such as HDPE and LDPE which have excellent water resistance, chemical resistance, and electrical insulation, combined with nylon materials with excellent strength and abrasion resistance, are applied in a mesh pattern around the core wire to improve strength to withstand bending and trampling, and to support applications in harsh environments requiring water resistance and chemical resistance. It is also used as an insulating material for audio wiring.

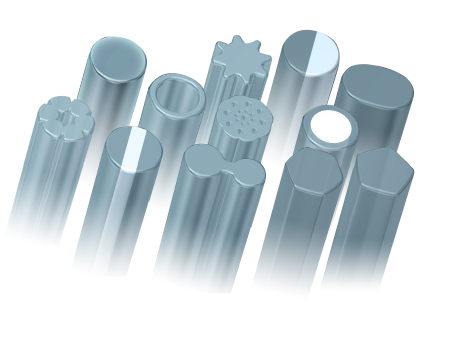

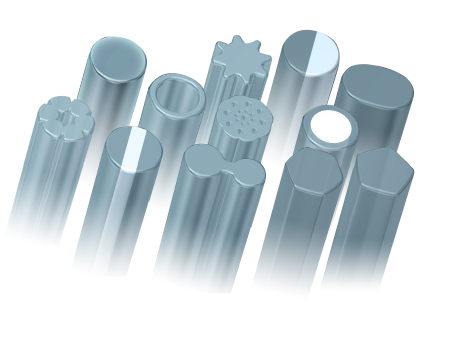

Many shape variations of monofilament fibers can be manufactured including different hollow section shapes, star shaped, ellipse/oval shaped, flower petal shaped, pentagon or hexagon shaped, two or more layers of different materials sandwiched together, core sheath and many more.

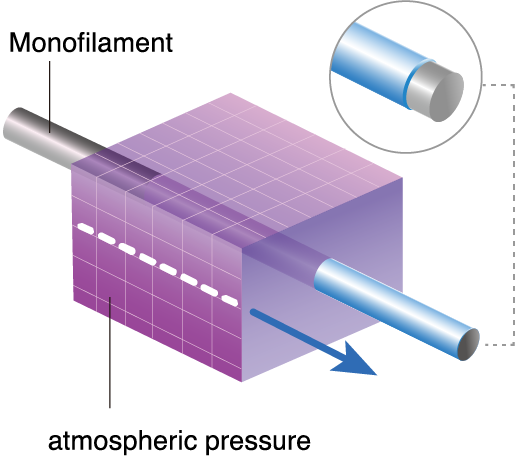

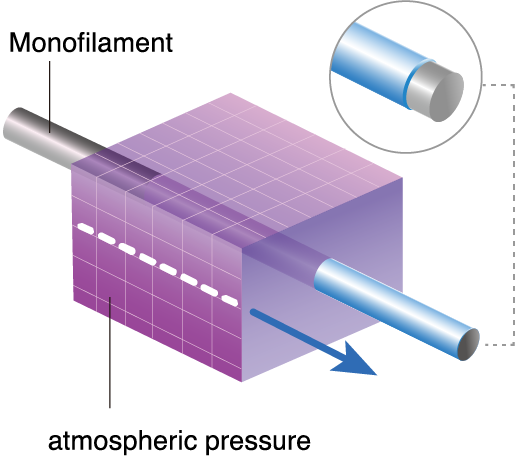

With our Plasma Rise Technology, the fibers surface can be functionalized as desired for your application. The fibers are given the innovative atmospheric pressure of the Plasma Rise process which was developed jointly with Plasma Concept Tokyo Co.

Colors are made to order to suit our customer’s needs. The quality of our coloring is unsurpassed.

The products are shipped in a delivery format that meets the customer's needs and application.

Our highly advanced technology have been developed for over 45 years.

-

Various Shapes

Many shape variations of monofilament fibers can be manufactured including different hollow section shapes, star shaped, ellipse/oval shaped, flower petal shaped, pentagon or hexagon shaped, two or more layers of different materials sandwiched together, core sheath and many more.

-

Plasma Rise Technology

With our Plasma Rise Technology, the fibers surface can be functionalized as desired for your application. The fibers are given the innovative atmospheric pressure of the Plasma Rise process which was developed jointly with Plasma Concept Tokyo Co.

-

Colors

Colors are made to order to suit our customers’ needs. The quality of our coloring is unsurpassed.

-

Delivery System

The products are shipped in a delivery format that meets the customer's needs and application.

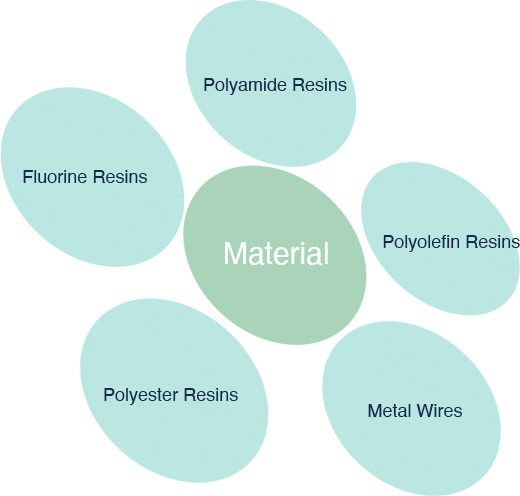

MATERIALS

This synthetic fiber was developed with the purpose of creating a silk-like material. It is supple and soft, with moderate elongation and strength. It is also water absorbent and feels good against the skin. It has excellent abrasion resistance and tenacity due to strong intermolecular interactions. This material is an integral part of the history of fishing line. We also have been developing Nylon 6 (homopolymer), Nylon 6/6 (copolymer), Nylon 12, and other polyamide resins since the company was founded.

Ultra-High Molecular Weight Polyethylene (UHMWPE) has a molecular weights between 1 to 7 million, considerably larger than normal polyethylene molecular weights of 20 to 300 thousand. It has an extremely high degree of crystallinity and a tensile strength about three times that of nylon. Specific gravity is low at 0.97. Because of its resistance to bending and breaking, it is used as an alternative material for ropes and metal wires. It has sliding properties second only to fluoropolymers and has excellent abrasion resistance.

Please contact about HDPE and LDPE materials.

Polyester resins have almost no water absorbency and excellent weather resistance, but their strength is inferior to that of nylon. Because of its heat resistance, insect resistance, and wrinkle resistance, it is widely used for suits, shirts, curtains, umbrellas, and fire hoses. PEN (polyethylene naphthalate), with its high rigidity, and PTT(polytrimethylene terephthalate), with its excellent stretch properties, are also available.

We manufacture very high strength fishing line using PVDF (polyvinylidene fluoride). We are experienced in manufacturing ETFE, PTFE, and EFEP. We can also produce round and sheath monofilaments to suppress melt fractures that tend to occur in high-speed extrusion molding. We have a twin-screw extruder for prototyping and production of high-performance materials.

-

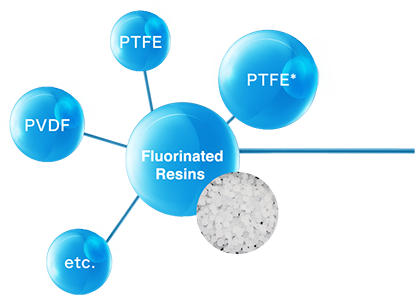

Fluorinated Resins

We manufacture very high strength fishing line using PVDF (polyvinylidene fluoride). We are experienced in manufacturing ETFE, PTFE, and EFEP. We can also produce round and sheath monofilaments to suppress melt fractures that tend to occur in high-speed extrusion molding. We have a twin-screw extruder for prototyping and production of high-performance materials.

-

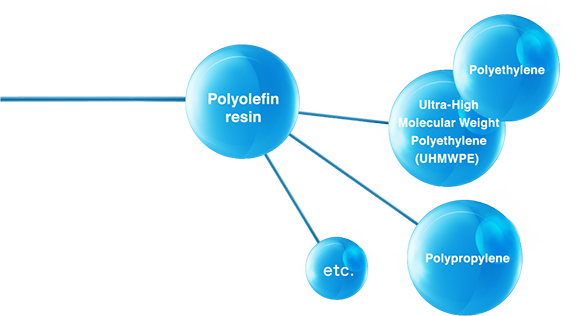

Polyolefin resin

Ultra-High Molecular Weight Polyethylene (UHMWPE) has a molecular weights between 1 to 7 million, considerably larger than normal polyethylene molecular weights of 20 to 300 thousand. It has an extremely high degree of crystallinity and a tensile strength about three times that of nylon. Specific gravity is low at 0.97. Because of its resistance to bending and breaking, it is used as an alternative material for ropes and metal wires. It has sliding properties second only to fluoropolymers and has excellent abrasion resistance.

Please contact about HDPE and LDPE materials. -

Polyester resin

Polyester resins have almost no water absorbency and excellent weather resistance, but their strength is inferior to that of nylon. Because of its heat resistance, insect resistance, and wrinkle resistance, it is widely used for suits, shirts, curtains, umbrellas, and fire hoses. PEN (polyethylene naphthalate), with its high rigidity, and PTT(polytrimethylene terephthalate), with its excellent stretch properties, are also available.

-

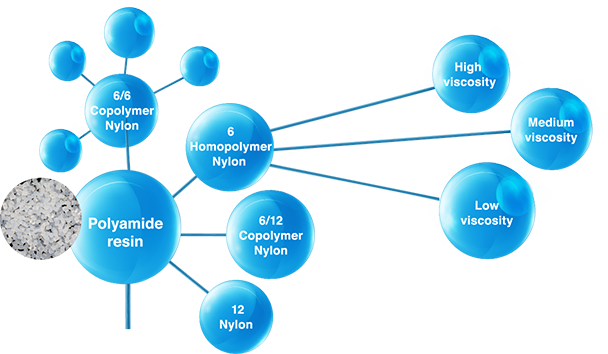

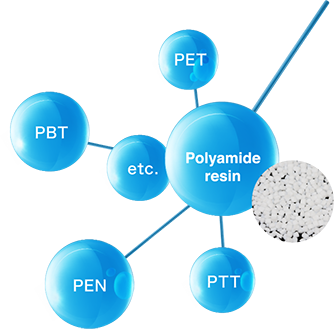

Polyamide resin

This synthetic fiber was developed with the purpose of creating a silk-like material. It is supple and soft, with moderate elongation and strength. It is also water absorbent and feels good against the skin. It has excellent abrasion resistance and tenacity due to strong intermolecular interactions. This material is an integral part of the history of fishing line. We also have been developing Nylon 6 (homopolymer), Nylon 6/6 (copolymer), Nylon 12, and other polyamide resins since the company was founded.

-

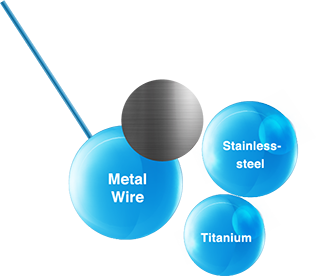

Metal Wire

We not only have resin, but also metal wire such as stainless-steel , galvanized steel, and copper . They can be used in a wide range of industries such as medicine, agriculture, construction, electronics, and jewelry.

SAVE THE WORLD OCEAN

Our products comply with the 3Rs and work together to protect

the ocean environment.

The 3Rs mean Reuse, Reduce, and Recycle.